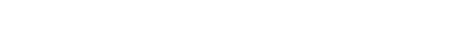

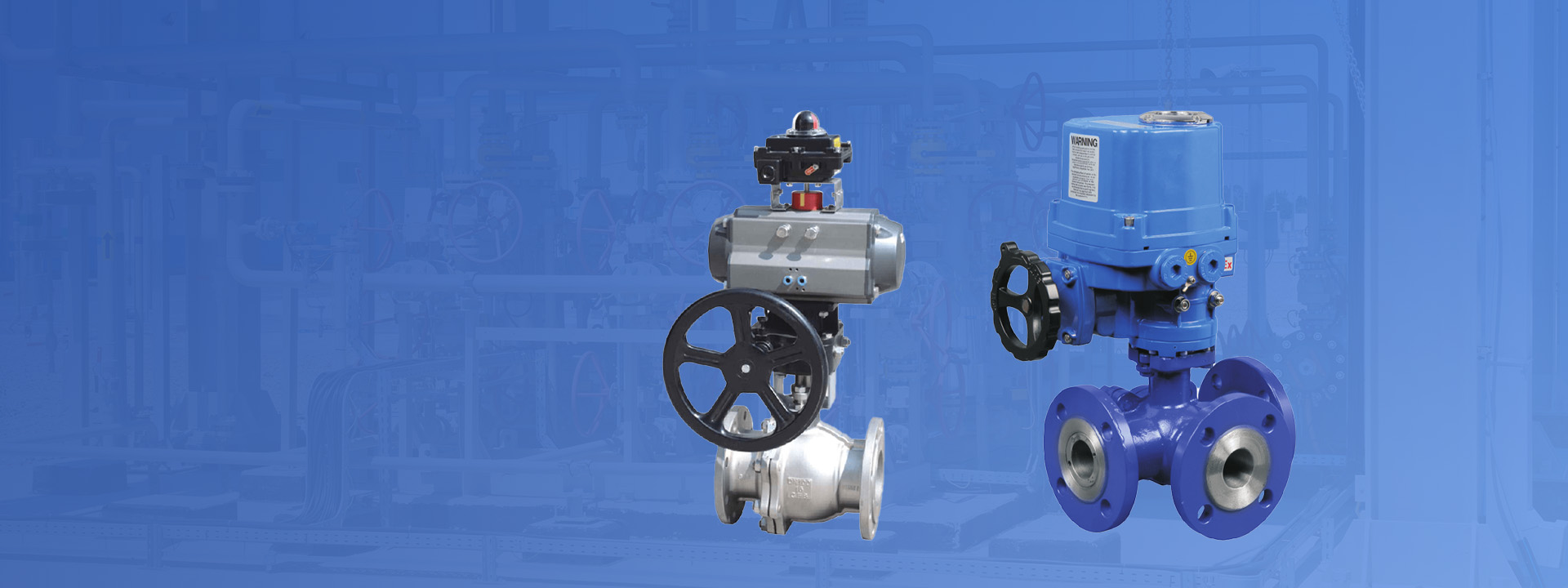

Intelligent accumulator type hydraulic control ball valve without electric switch, heavy hammer hydraulic control water and electricity square ball valve

The intelligent accumulator type hydraulic control ball valve with no electric switch and heavy hammer hydraulic control water and electricity square ball valve are designed and manufactured according to GB/T14478-1993 and GB/T12237-1989, and installed at the inlet of the hydropower station turbine as the inlet valve of the turbine. When working, the valve cooperates with the pipeline host, and according to the principle of hydraulic transition process, through the effective setting of the electro-hydraulic control program, reliable shut-off of the pipeline is achieved, effectively eliminating water hammer in the pipeline, and the valve can be closed without electricity, which plays a role in protecting the safety of the pipeline system.

The intelligent accumulator type hydraulic control ball valve and heavy hammer type hydraulic control ball valve produced by our company use gas compression energy as the power source for automatic valve closing, adopt PLC intelligent control system, have low flow resistance coefficient, high degree of automation, and are equipped with fully open and fully closed dual position locking devices. They have complete functions and stable and reliable performance. Based on extensive collection, research and summary of the performance of similar products at home and abroad, our company has introduced multiple research results from the valve, hydraulic, electrical and other industries, and developed a new generation of intelligent, efficient and energy-saving products.

Product Features

Hydraulic control heavy hammer ball valve is a type of valve that relies on the potential energy of a heavy hammer to automatically close the valve without the need for power. It is suitable for hydraulic power generation, water lifting engineering, and oil and gas transmission pipelines that need to be urgently closed due to faults, but cannot achieve the function of pipe interruption. The closure is completed in two stages, fast and slow, which not only meets the requirements of rapid closure but also avoids the harm of water hammer caused by medium flow; From a structural perspective, the use of a three-stage upper seal (inlet seal+outlet seal) has reliable sealing performance, easy maintenance, and the most superior feature is that the flow resistance coefficient is the smallest compared to other types of valves (such as gate valves, butterfly valves, etc.), with low operating energy consumption and high efficiency. From a control mechanism perspective, when closing the valve, it relies on the potential energy of the heavy hammer, which is more electric and hydraulic, without the need for a constant power supply. The hydraulic heavy hammer ball valve can be operated on site or remotely controlled by a PLC to achieve less or no human operation. The hydraulic control heavy hammer ball valve is equipped with a dual pump (electric pump+manual pump) system, which can manually open or close the ball valve in the absence of a power source.

1. The hydraulic control heavy hammer ball valve has complete electro-hydraulic control functions and can be used as an independent system for on-site debugging without the need for additional configuration. Control: It can also be used as a device unit of a distributed control system (DCS), with a central computer for centralized control and management through I/O channels, and can achieve linkage operation with other pipeline equipment such as water pumps, water turbines, and bypass valves; And equipped with manual function, it can also be manually opened and closed without power supply, meeting the requirements of valve debugging and control under special working conditions, with good controllability. The electro-hydraulic control system is designed with mobile multiple adjustment points, which can set the opening and closing program according to different pipeline control requirements, ensuring that the valve can automatically open and close at the predetermined time and angle in two stages: fast and slow; And it can achieve power-off shutdown, effectively eliminating destructive water hammer in the pipeline, preventing water pumps and water turbines from escaping accidents, effectively reducing pressure fluctuations in the pipeline system, and ensuring the safe and reliable operation of equipment

2. Reliable sealing performance: The PTFE elastic material sealing ring is embedded in the stainless steel valve seat, and the metal valve seat end is equipped with a spring to ensure sufficient pre tightening force of the sealing ring. When the sealing surface of the valve wears out during use, the valve continues to ensure good sealing performance under the action of the spring.

3. Fireproof structure: In order to prevent the PTFE sealing ring from burning out due to sudden heat or fire, causing significant leakage and fueling the fire, a fireproof sealing ring is installed between the sphere and the valve seat. When the sealing ring burns out, the valve seat sealing ring is quickly pushed onto the sphere by the spring force, forming a metal to metal seal and achieving a certain degree of sealing effect. The fire resistance test meets the requirements of API6FA and AP1607 standards.

4. Automatic pressure relief function: When the pressure of the medium that stops leaking in the valve chamber abnormally increases beyond the preload force of the spring, the valve seat will retract and detach from the ball, achieving the effect of automatic pressure relief. After pressure relief, the valve seat will automatically reset.

5. Drainage pipeline: A drainage system is installed under the valve body to check if there is any leakage at the valve seat. During operation, when the valve is fully open or fully closed, the pressure in the middle chamber can be relieved, and the packing can be directly replaced to discharge the residual material in the middle chamber and reduce the pollution of the medium to the valve. Auxiliary sealing setting system (please specify when ordering). 6. This valve is designed with an auxiliary seat emergency sealing system. In the event of seal damage or emergency situations that prevent sealing, the sealing surface can be repaired by injecting the corresponding sealant through the auxiliary sealing system to achieve emergency sealing. The device can also be injected with the corresponding cleaning agent to clean the seal.

7. Can be hydraulically or mechanically locked to ensure that the heavy hammer does not fall during operation.

8. Adopting a specially designed leak free electromagnetic ball valve, the system has good pressure holding performance.

9. There are two pressure compensation methods, stroke switch and electric contact pressure gauge, to ensure that the butterfly valve will not automatically close due to hydraulic system leakage.

10. Can be controlled by PLC, with high degree of automation

11. Widely applicable for cutting off or circulating media in hydraulic power generation, water lifting engineering, oil and gas transmission pipelines.

首页

首页

Product

Product  News

News  联系我们

联系我们