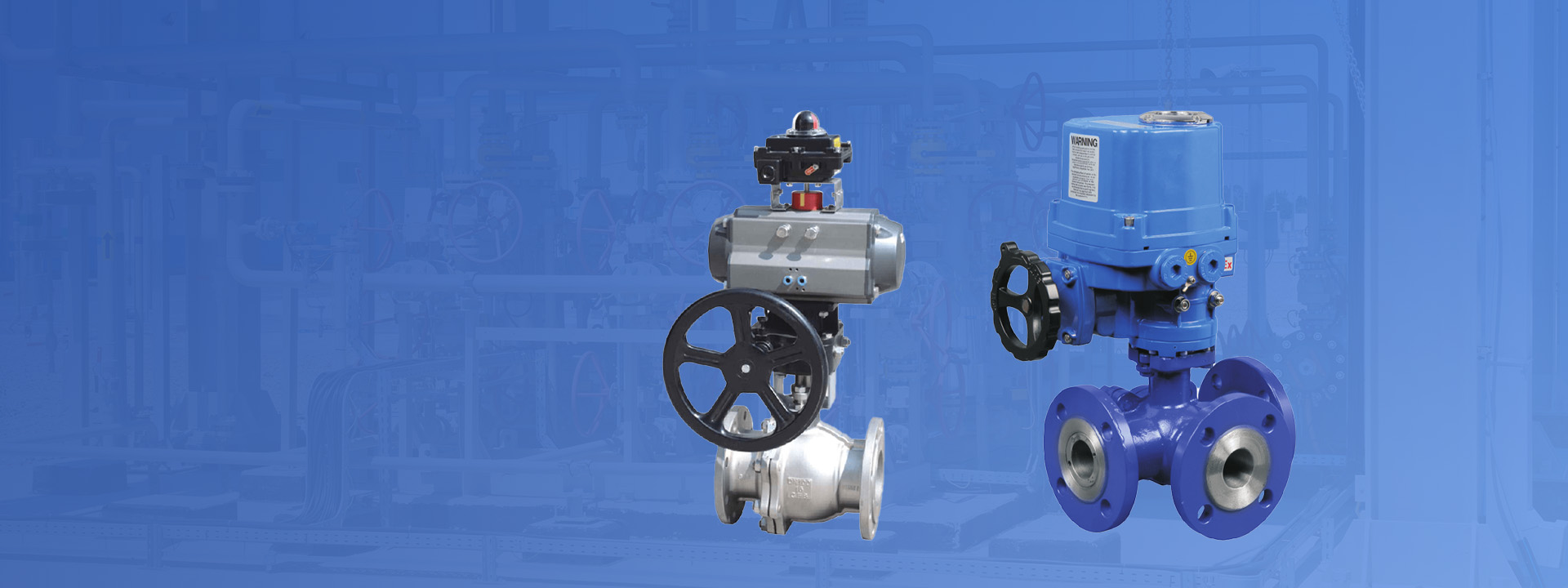

WCB cast steel worm gear worm gear transmission steel lined PTFE flange ball valve F46/PFA/PTFE

Worm gear steel lined PTFE ball valve is a widely used valve type in various industrial applications, designed based on worm and worm gear transmission mechanisms. This mechanism enables valves to precisely control the opening and closing of fluids. Worm gear is usually a threaded rod, while worm gear is a disc with gears. The worm gear rotates to push the worm wheel, thereby opening or closing the valve. One of the advantages of this mechanism is that it can provide highly precise control, and a significant feature of the worm gear steel lined PTFE ball valve is its material construction. Steel lined PTFE refers to a valve whose interior is made of tetrafluoroethylene (also known as polytetrafluoroethylene or PTFE), while its exterior is made of steel. The advantage of this structure is that tetrafluoroethylene has excellent chemical stability and low friction coefficient, making it an ideal choice under corrosive fluids and high temperature conditions. The outer layer of steel provides strong mechanical strength, ensuring the stability of the valve under high pressure.

The working principle of the worm gear steel lined PTFE ball valve is relatively simple but efficient. When the worm is rotated, the worm wheel will move linearly along the worm, thereby changing the position of the ball valve. When the worm gear rotates to push in or pull out the worm, the valve core of the ball valve will rotate, changing the flow path of the fluid. The advantage of this type of institution lies in its precision, which enables rapid response, quick closure, and precise flow and pressure regulation. Worm gear steel lined PTFE ball valves play a key role in many application fields. Firstly, they are widely used in the chemical industry. Due to the corrosion resistance of tetrafluoroethylene, these ball valves are very useful in handling acids, alkalis, solvents, and other corrosive chemicals. Secondly, worm gear ball valves are widely used in the oil and gas industry. They are used to control the flow of crude oil and natural gas, as well as various processes in oil extraction and refining. In addition, these valves are also used in the food and pharmaceutical industries to process the production of food and drugs. Due to the hygiene performance and high temperature resistance of tetrafluoroethylene, their application in these fields is very important. One of the advantages of the worm gear steel lined PTFE ball valve is its reliability. They usually have a long lifespan and can withstand continuous use under harsh environmental conditions. This makes them very popular in industrial processes because they can reduce downtime and maintenance costs. In addition, these valves can be customized according to the needs of different applications, including different specifications, pressure ratings, and connection methods. In summary, the worm gear steel lined PTFE ball valve is a key component in modern engineering, and its design and performance make it suitable for a variety of challenging applications. Their precise control, material corrosion resistance, and reliability make them an indispensable part of industrial processes. Whether in the fields of chemical, oil and gas, food manufacturing, or pharmaceuticals, these valves play a crucial role in ensuring smooth production and daily life. The design and performance of the worm gear steel lined PTFE ball valve not only improve industrial efficiency, but also provide a solid foundation for sustainable development and innovative engineering.

首页

首页

Product

Product  News

News  联系我们

联系我们