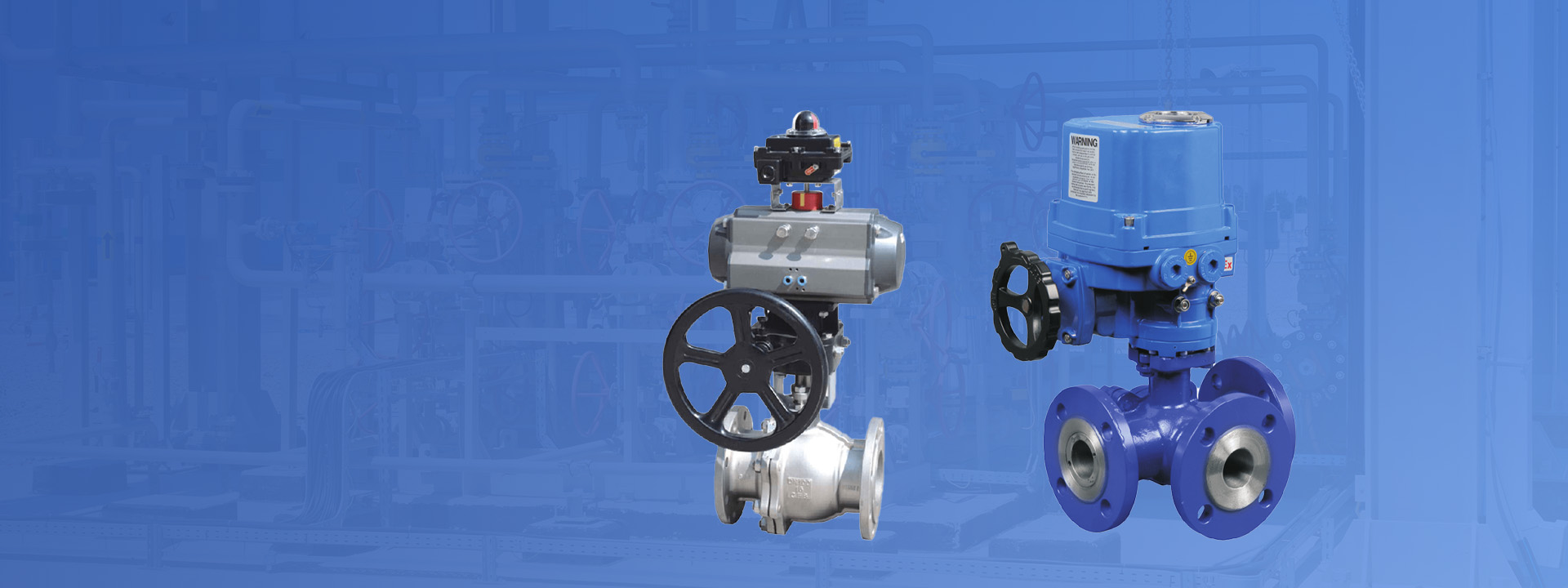

Manual high vacuum ISO flange ball valve

Vacuum ISO connected ball valve is a commonly used control valve in vacuum systems. It adopts ISO standard connection method and can be easily connected with other vacuum equipment to control the on/off and regulation of fluids.

Introduction to Vacuum ISO Connection Ball Valve

Overview of Vacuum System Vacuum technology is a technology that studies working under conditions where gas pressure is lower than atmospheric pressure. Vacuum systems are widely used in scientific research experiments, semiconductor manufacturing, optical equipment, aerospace, and other industrial fields. In order to achieve control and regulation of fluids in vacuum systems, vacuum ISO connected ball valves have emerged.

Structure and working principle: A vacuum ISO connected ball valve consists of a valve body, valve stem, valve ball, valve seat, and handle. The valve body adopts ISO standard connection ports, making it easy to connect with other vacuum equipment. The valve stem and valve ball are tightly integrated through special design, and the valve ball can rotate on the valve seat to achieve fluid on/off and regulation. When the handle rotates, the opening degree of the valve ball will also change accordingly, thereby adjusting the fluid flow rate. The ball valve has a compact structure, easy operation, and good sealing performance.

Features and advantages: Vacuum ISO connected ball valves have the following features and advantages:

1. ISO standard connection: Using ISO standard connection interface, it has strong compatibility with other vacuum equipment and can be flexibly assembled and disassembled. 2. Good sealing performance: The tight combination between the ball valve and the valve seat of the ball valve enables the valve to have good sealing performance in the closed state, effectively preventing gas leakage. 3. Easy operation: The handle of the ball valve is easy to rotate and the switch is quick, making fluid control more convenient. 4 Wide applications: Vacuum ISO connected ball valves can be used for controlling and regulating various gas fluids, suitable for various vacuum systems. 5. Good corrosion resistance: Ball valves are often made of corrosion-resistant materials such as stainless steel, which can adapt to various working environments.

When installing and maintaining the vacuum ISO connection ball valve, it is necessary to ensure that the connection port is clean and tightly connected. Before use, the sealing performance and operational flexibility of the valve should be checked. Regular maintenance should be carried out on ball valves to clean the valve body, stem, and ball, and to add lubricants in a timely manner to ensure the normal operation of the valve.

When using a vacuum ISO connected ball valve, the following precautions should be taken:

1. Valve pressure range: The appropriate pressure range should be selected according to the actual working conditions to avoid valve damage caused by overpressure. Material of Valve 2: Select the appropriate valve material based on the properties of the working medium to ensure the corrosion resistance of the valve. 3. Valve operation: Avoid excessive force or rapid operation of the valve to prevent damage to the valve or affect its sealing performance. 4. Maintenance: Regularly maintain the ball valve to ensure its normal operation and sealing performance.

Summary: Vacuum ISO connected ball valve is a commonly used control valve in vacuum systems, which has the advantages of ISO standard connection, good sealing performance, easy operation, and wide application. Before use, attention should be paid to the installation quality and the pressure range of the valve, and regular maintenance should be carried out. By reasonable selection and use, vacuum ISO connected ball valves can stably and reliably achieve fluid control and regulation in vacuum systems.

首页

首页

Product

Product  News

News  联系我们

联系我们