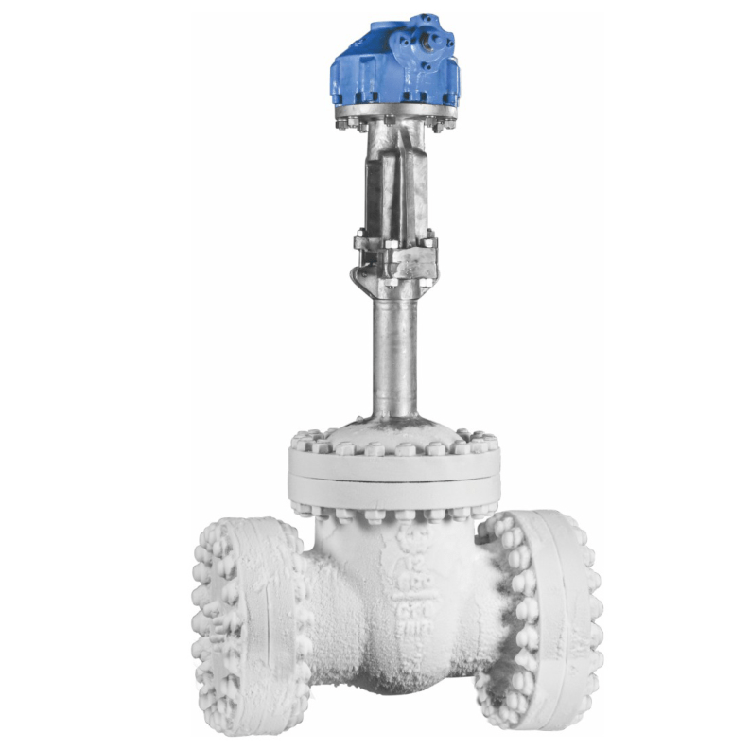

Ultra low temperature flange high-pressure gate valve

Ultra low temperature flange high-pressure gate valve is a valve that operates in extreme low temperature environments, mainly used for flow control of ultra-low temperature media such as liquefied natural gas (LNG), liquid nitrogen, and liquid oxygen. This type of valve has a special structure that can maintain high sealing and reliability under low temperature conditions, ensuring the safe operation of the system. The following is a detailed explanation of the ultra-low temperature flange high-pressure gate valve:

1. Structural characteristics: Ultra low temperature flange high-pressure gate valves are usually composed of valve body, valve cover, valve stem, gate plate, sealing components, etc. The valve body and valve cover are usually made of high-strength materials, such as stainless steel, to withstand the challenges of high pressure and low temperature environments. The valve stem is connected to a handle or actuator, used to control the movement of the gate.

2. Sealing performance: Due to the special properties of ultra-low temperature media, special attention should be paid to sealing performance in the design of ultra-low temperature flange high-pressure gate valves. The sealing parts of valves are usually made of high-performance sealing materials, such as polytetrafluoroethylene (PTFE), fluororubber, etc., to ensure reliable sealing in low temperature environments and prevent medium leakage.

3. Low temperature material selection: In ultra-low temperature environments, conventional materials will become brittle, lose strength and toughness. Therefore, the key components of ultra-low temperature flange high-pressure gate valves need to be made of low-temperature resistant materials, such as austenitic stainless steel, nickel alloys, etc., to ensure the reliability and durability of the valve at extreme low temperatures.

4. Anti freezing design: In ultra-low temperature environments, liquid media are prone to freezing, causing valves to fail to open and close normally. Therefore, ultra-low temperature flange high-pressure gate valves usually consider anti freezing design by using heating devices or cooling media to maintain the normal operating temperature of the valve.

5. Safety performance: The design and manufacturing of ultra-low temperature flange high-pressure gate valves need to comply with strict safety standards to ensure the reliability and safety of the valves in low-temperature and high-pressure environments. Valves are typically subjected to rigorous testing and certification to ensure their reliable operation under ultra-low temperature conditions.

6. Application areas: Ultra low temperature flange high-pressure gate valves are widely used in liquefied natural gas (LNG) receiving stations, liquid oxygen, liquid nitrogen storage and transportation systems, etc., for controlling the flow and stopping of media.

7. Maintenance and upkeep: Due to the high requirements for equipment in ultra-low temperature environments, valve maintenance and upkeep are crucial. Regularly check the sealing performance, material condition, and operation of the heating or cooling system of the valve to ensure that it can work reliably when needed.

In summary, ultra-low temperature flange high-pressure gate valves play a crucial role in extreme low temperature environments, ensuring the flow control of ultra-low temperature media and the safe operation of the system. Its special structural design, sealing performance, material selection, and safety performance make it an indispensable and important equipment under ultra-low temperature conditions.

首页

首页

Product

Product  News

News  联系我们

联系我们