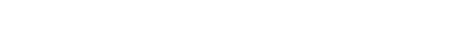

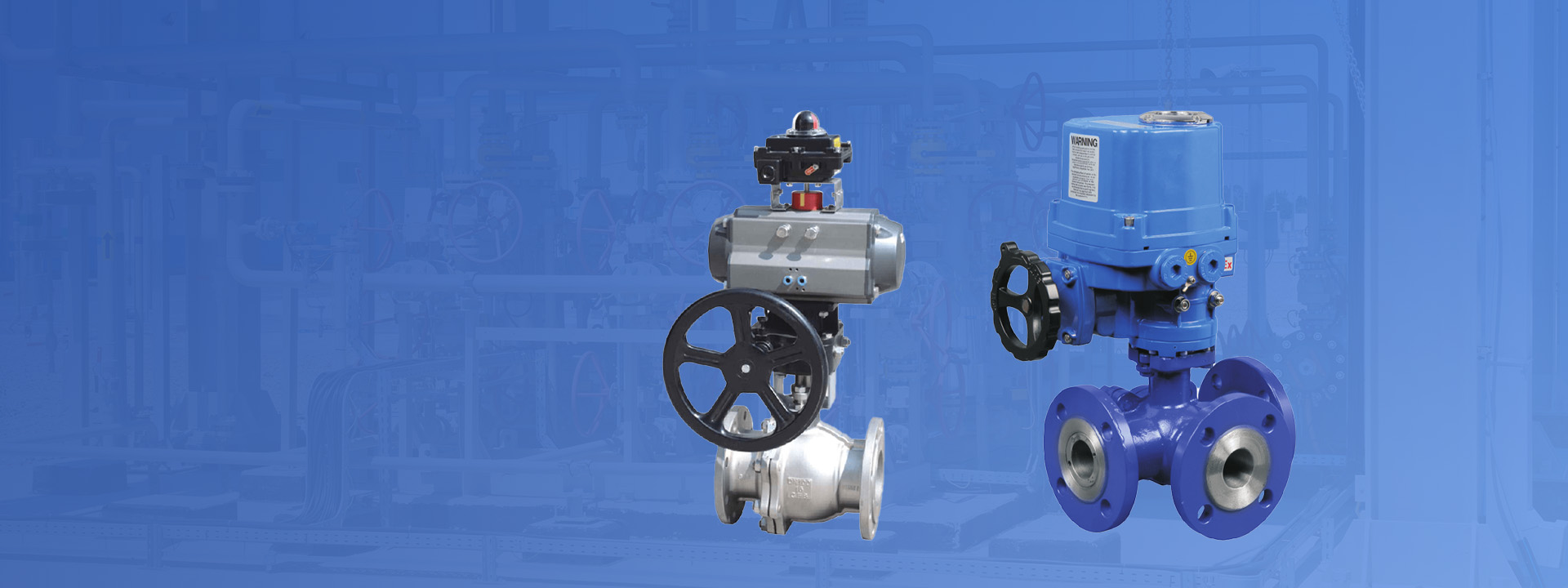

Thin film pneumatic fluorine lined flow control valve

The pneumatic film lined fluorine regulating valve adopts a top guide structure and is equipped with a lightweight and small multi spring pneumatic film actuator. It has the advantages of compact structure, light weight, sensitive action, S-shaped fluid channel, low pressure drop loss, large valve capacity, precise flow characteristics, and easy disassembly and assembly. Due to the high-pressure injection molding process, the parts of the valve that come into contact with the medium are lined with corrosion-resistant and anti-aging polytetrafluoroethylene (F46) or PFA, and the packing box is sealed with polytetrafluoroethylene bellows. Therefore, this regulating valve can be widely used in industries such as chemical, petroleum, metallurgy, pharmaceuticals, and power to control the process of strong corrosive media such as acids and alkalis, as well as toxic and volatile gas and liquid media.

1. Corrosivity: The valve body cavity, valve core, valve seat, and valve stem are all lined with 2.5-3mm thick F46 or PFA, which can resist acid, salt, and strong corrosion. 2. Good sealing performance: Due to the use of PTFE corrugated tubes and double sealing of the packing box, there is no leakage. 3. Small leakage: Due to the soft sealing structure of the valve core and seat, the leakage is lower than the IV level leakage standard in the national standard GB/T4213. 4. The actuator adopts a lightweight and small multi spring actuator, with small volume, light weight, and high adjustment accuracy

首页

首页

Product

Product  News

News  联系我们

联系我们