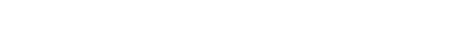

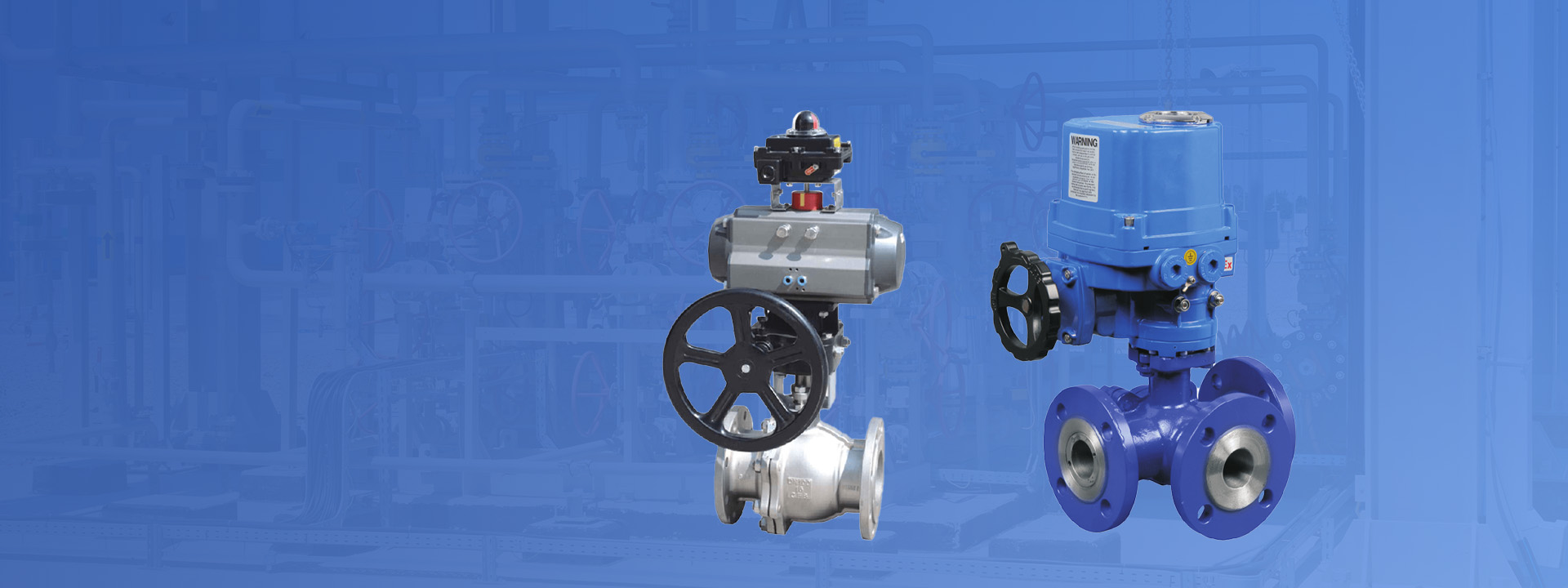

Cast steel wear-resistant metal hard sealed flange ball valve

Q41H metal hard sealed flange ball valves are mainly divided into handle switches, worm gear operated switches, and can also be intelligently controlled by electric or pneumatic actuators. It can also be divided into floating ball valves and fixed ball valves. The valve stem of the ball valve can be extended or forged steel technology can be used. The valve seat can be welded with Stellite (STL), tungsten carbide (W.C), and chromium carbide (N.C) to provide wear resistance and withstand high temperatures.

Metal seat flange ball valves with ISO 5211 upper flange can be equipped with handle switches, gear operations, pneumatic actuators, and electric actuators

Main options: Stainless Steel 304, Stainless Steel 316L, Cast Steel WCB Sphere: Stainless Steel 304, Stainless Steel 316L Seat: Graphite Gasket, STL Alloy Seat Type: Floating Ball, Fixed Ball Standard: ANSI, JIS, EN, DIN Drive mode: Handle, Gear, Pneumatic, Electric

The manual part can use steel plate pressed handles or stainless steel cast handles. The handle is equipped with a limit structure, which is set at the opening and closing position of the valve. When the valve is used on a key device, there is a locking hole on the limit block that can lock the switch position to avoid accidental operation. There are obvious open and close marks on the handle.

The valve stem adopts A182F (1Cr13) integral forging and modulation treatment, with a hardness of HB220-250. The valve stem and handle are connected by flat keys, splines, or square heads, which have strong universality and are easy to disassemble and assemble. The valve stem is equipped with an anti blowout structure.

The packing of the valve adopts braided, flexible graphite sealing ring or PTFE sealing ring, which enables the valve stem to achieve reliable sealing under certain lubrication conditions.

As needed, ball valves can be designed with anti-static structures, with conductive springs installed between the ball and the valve stem, as well as between the valve stem and the valve body, to prevent static electricity from igniting flammable substances and ensure the safety of the valve. The security of the system.

There are various forms of sealing pairs. According to different working conditions, structures such as soft seals, hard seals, and fire-resistant valve seats can be selected; Below DN150 is in the form of a floating ball, and below DN200 is in the form of a fixed ball. Auxiliary sealing structures can be installed at the valve seat of the ball valve, and grease injection valves can be installed at the valve seat and stem. In emergency situations, temporary sealing can be provided, and the stem can be extended as needed to be suitable for buried locations.

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们