Valve selection

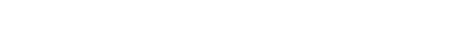

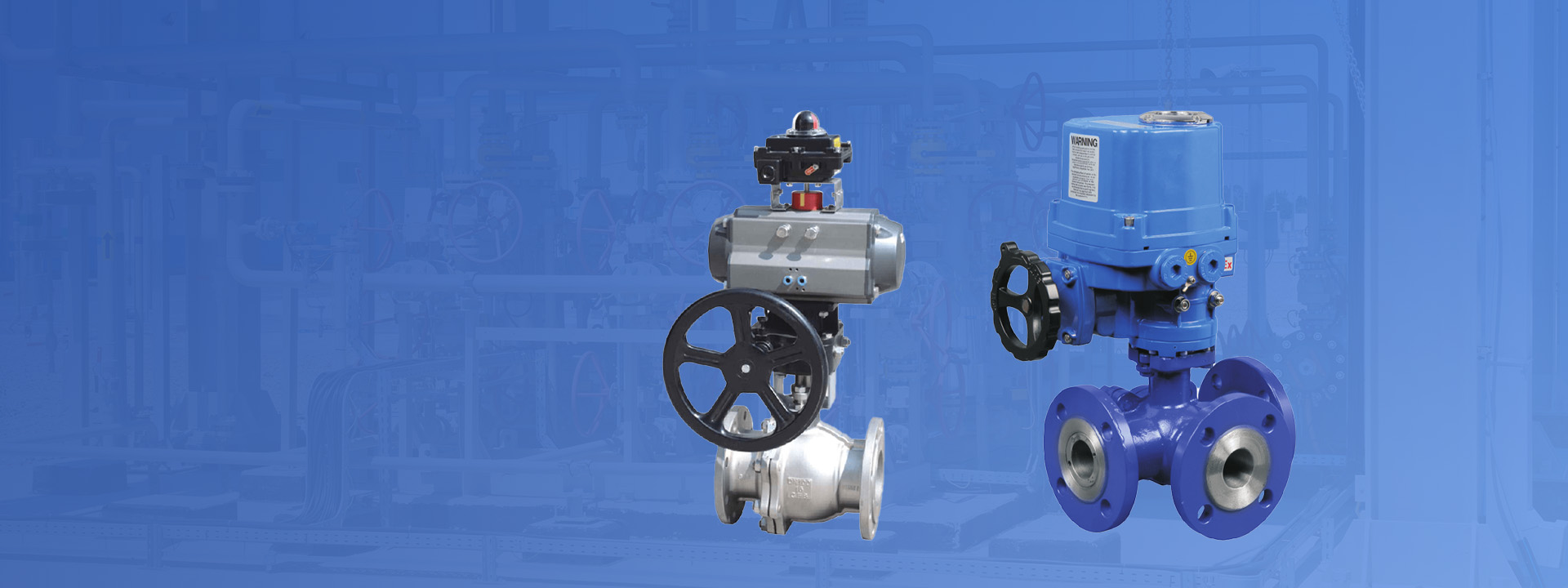

Carbon cast steel manual worm gear transmission upper mounted flange eccentric hemispherical valve

Worm Gear and Worm Mounted Eccentric Half Ball Valve: An industrial tool for precise fluid control. Worm Gear and Worm Mounted Eccentric Half Ball Valve is a high-precision control valve widely used in the field of industrial fluid control. Its unique design combines the characteristics of a worm gear mechanism and an eccentric hemispherical valve, making it an ideal choice for applications that require precise flow control. In this article, we will delve into the design, working principle, application areas, and key role of this valve in industrial fluid control.

1. Precise control of worm gear mechanism: Worm gear mechanism is a mechanical transmission system widely used to convert rotational motion into linear motion. In the worm gear mounted eccentric hemispherical valve, the function of this mechanism is to control the position of the valve ball, thereby accurately adjusting the flow rate of fluid through the valve. A worm gear is usually a disc with a screw shaped worm on it. When the worm gear rotates, the rotation of the worm will cause linear displacement of the valve ball, thereby changing the degree of valve opening. This mechanical mechanism provides very high control accuracy, enabling the valve to stably achieve the required flow control under various operating conditions. 2. Fluid control performance of eccentric hemispherical valve: The design of eccentric hemispherical valve is based on a hemispherical valve body, and the valve ball or spool has an eccentric shape. This eccentric design allows the valve to control fluid flow in a very precise manner. Continuous flow control from fully closed to fully open can be achieved by rotating the valve ball. This characteristic is crucial for applications that require maintaining accurate flow in industrial processes. 3. Advantages of the upper mounted design: In the design of the worm gear upper mounted eccentric hemispherical valve, the worm gear mechanism is located at the top of the valve, and the movement of the valve ball is controlled by the rotation of the worm gear. This top-down design has several advantages. Firstly, it makes the valve easier to maintain and replace, as the mechanical components are located at the top of the valve without the need to disassemble the entire valve. Secondly, it allows for a wider range of opening degrees and more complex control operations, making the valve suitable for various applications.

4. Application field: Worm gear mounted eccentric hemispherical valves are commonly used in industrial applications that require high-precision flow control. They are widely used in chemical, petroleum, natural gas, food, pharmaceutical, water treatment, and other fields. Here are some examples of application areas: - Chemical industry: used to control the flow of various chemicals and liquids, ensuring the stability and safety of chemical processes- Petroleum and natural gas industry: used for precise control of the flow of crude oil, natural gas, and refined products in oil wells, pipelines, and refineries- Food and pharmaceutical industry: used for precise control of liquid and gas flow in food and pharmaceutical production, ensuring product quality and compliance- Water treatment industry: used to control fluid flow and pressure in water supply, wastewater treatment, and sewage treatment processes to meet environmental standards- Industrial processing: used to control fluid flow in various industrial processes, including temperature control and mixing operations.

5. Conclusion: Worm gear mounted eccentric hemispherical valve is an industrial valve known for its high-precision fluid control capability and mechanical reliability. This type of valve plays a crucial role in various industrial applications, ensuring process stability, product quality, and compliance. The combination of its unique worm gear mechanism and eccentric hemispherical valve makes it one of the preferred fluid control solutions for engineers and operators.

简体中文

简体中文 Japanese

Japanese Korean

Korean Russian

Russian 繁体中文

繁体中文

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们