Valve selection

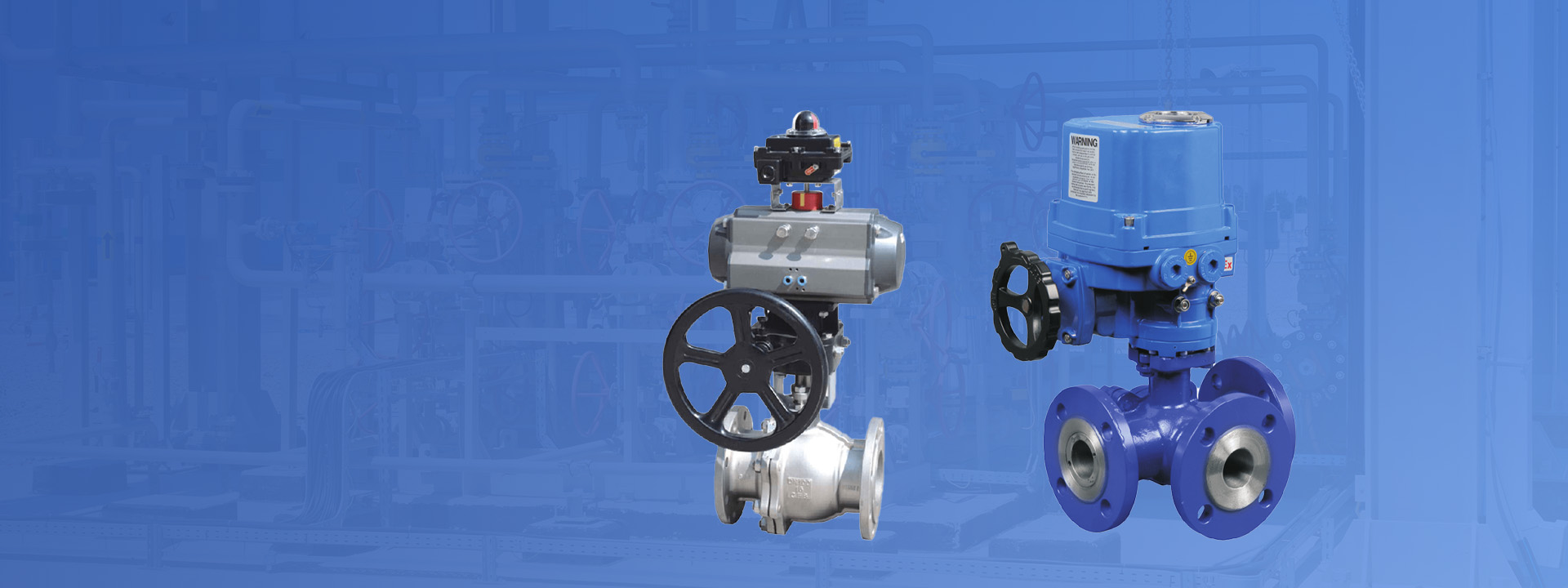

CF8/304 stainless steel worm gear prevents medium solidification, insulation jacket flange ball valve BQ41F

CF8/304 stainless steel worm gear insulation jacket flange ball valve BQ41F (Stainless Steel Worm Gear Insulation Jacketed Flanged Ball Valve) is a specially designed ball valve that combines the characteristics of stainless steel material, worm gear transmission, insulation jacket, and flange connection. This type of valve is commonly used in industrial fluid control systems for applications that require maintaining fluid temperature under harsh environmental conditions. The insulation medium is usually steam or thermal oil, which enters through the side insulation medium inlet and exits through the outlet, circulating to heat and insulate the medium inside the valve.

1. Stainless steel material: The main structure of this ball valve is made of stainless steel, usually stainless steel 304 or stainless steel 316, which gives it excellent corrosion resistance and durability. Stainless steel is an ideal material for handling various liquids and gases, including corrosive media. 2. Worm gear transmission: The worm gear transmission mechanism is a mechanical device used to convert rotational motion into linear motion. In this type of ball valve, worm gear transmission is used to control the position of the valve ball, thereby adjusting the fluid flow rate. Worm gear transmission provides precise control and can be used to achieve precise fluid regulation. 3. Insulation jacket: The insulation jacket is a jacket structure installed outside the ball valve to maintain the temperature of the fluid in the pipeline. This is crucial for applications that require maintaining temperature during fluid transport, such as the chemical or food industries in low or high temperature environments. 4. Flange connection: Flange connection is a part of this ball valve used to connect the valve to the pipeline system. The flange connection provides a stable connection and allows for easy maintenance and replacement of the valve. 5. Application areas: Stainless steel worm gear insulation jacket flange ball valves are commonly used in industrial applications that require maintaining fluid temperature. Here are some examples of application areas: - Chemical industry: used to control the flow of chemicals and liquids, ensuring that processes operate at specific temperatures to meet production requirements- Food and beverage industry: used in food and beverage processing to ensure that fluids maintain the required temperature under hygienic conditions- Oil and gas industry: used to maintain the temperature of crude oil and refined products during oil extraction and refining processes to ensure process stability- Chemical industry: used to process fluids in chemical reactions, ensuring that the reactions occur at the required temperature- Heating and cooling system: used in heating and cooling systems to maintain fluid operation within a suitable temperature range- Wastewater treatment: used to maintain fluid temperature during the wastewater treatment process to ensure effective treatment and disinfection. 6. Structure and working principle: The structure of the stainless steel worm gear insulation jacket flange ball valve includes the valve body, valve ball, worm gear transmission, insulation jacket, flange connection, and control system. When the operator rotates the worm gear drive, the valve ball rotates inside the valve body, thereby controlling the flow of fluid. At the same time, the insulation jacket can wrap around the valve body and maintain the temperature of the fluid through external media such as steam or hot water, ensuring that it maintains the required temperature in the pipeline. 7. Advantages and benefits: - Temperature maintenance: The insulation jacket structure can maintain fluid temperature and is suitable for applications that require operation at specific temperatures- Corrosion resistance: Stainless steel material has corrosion resistance and is suitable for environments with corrosive media- Precise control: Worm gear transmission provides precise fluid control, making it suitable for applications that require high-precision control- Maintainability: The flange connection makes the valve easy to maintain and replace, reducing downtime- Widely applicable: Suitable for multiple industrial fields, meeting the needs of different applications. 8. Conclusion: Stainless steel worm gear insulated jacket flange ball valve is a multifunctional valve suitable for applications that require maintaining fluid temperature in industrial processes. Its stainless steel structure, worm gear transmission, insulation jacket, and flange connection provide highly precise fluid control and temperature maintenance capabilities, making it the preferred choice for engineers and operators. This type of valve plays an important role in multiple industries, ensuring process stability, product quality, and safety.

简体中文

简体中文 Japanese

Japanese Korean

Korean Russian

Russian 繁体中文

繁体中文

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们