Valve selection

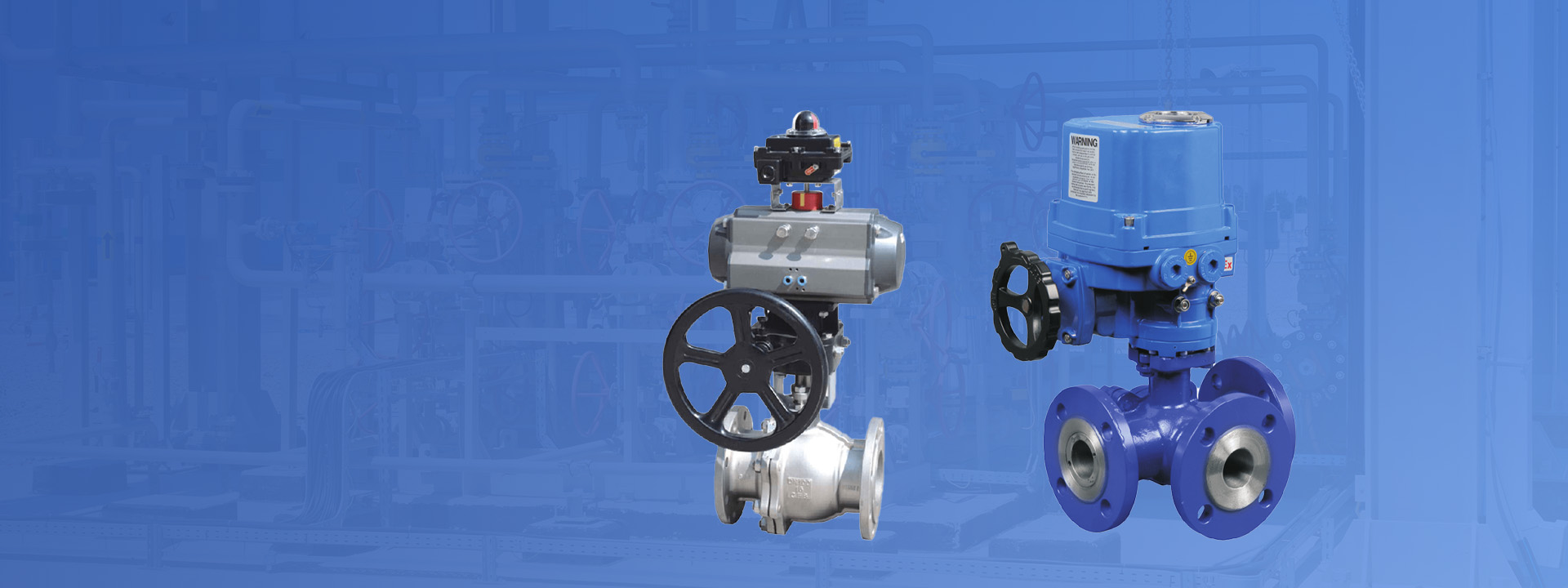

Worm gear steel lined PTFE butterfly valve

FEP lined butterfly valve/gear operation/handle specifications FEP, PFA, PCTFE, PTFE, PO lined butterfly valve (lined valve) is suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid, as well as various organic acids, strong acids, and strong oxidants

The gear operated clamp type lining butterfly valve adopts a clamp type anti-corrosion fluorine butterfly valve that integrates a two-piece valve body, valve seat, and valve body lining.

When the valve is in operation, only the plastic valve seat and lining plastic butterfly plate come into contact with the medium. The product can withstand corrosion from other media except for molten alkali metals and fluorine elements. The valve stem and valve disc (forging) are integrated, and the lining is evenly coated on a surface layer. The inner surface of the valve body channel is smooth, with low fluid resistance, high CV value, strong flow capacity, moderate torque, and a four stage sealing structure. The sealing surface is matched with an elastic liner, and the valve seat is made of heat-resistant SI rubber to achieve no medium leakage.

Chinese lined clamp butterfly valve manufacturers produce domestically produced anti-corrosion butterfly valve types, and lined clamp butterfly valves are the cheapest. The valve body is usually made of cast steel material.

The lining material is chosen by the customer, and the opening device is diversified. The handle, gear operation, pneumatic, and electric all work because the upper flange connection plate complies with ISO 5211.

简体中文

简体中文 Japanese

Japanese Korean

Korean Russian

Russian 繁体中文

繁体中文

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们