Valve selection

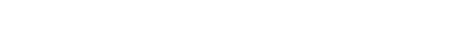

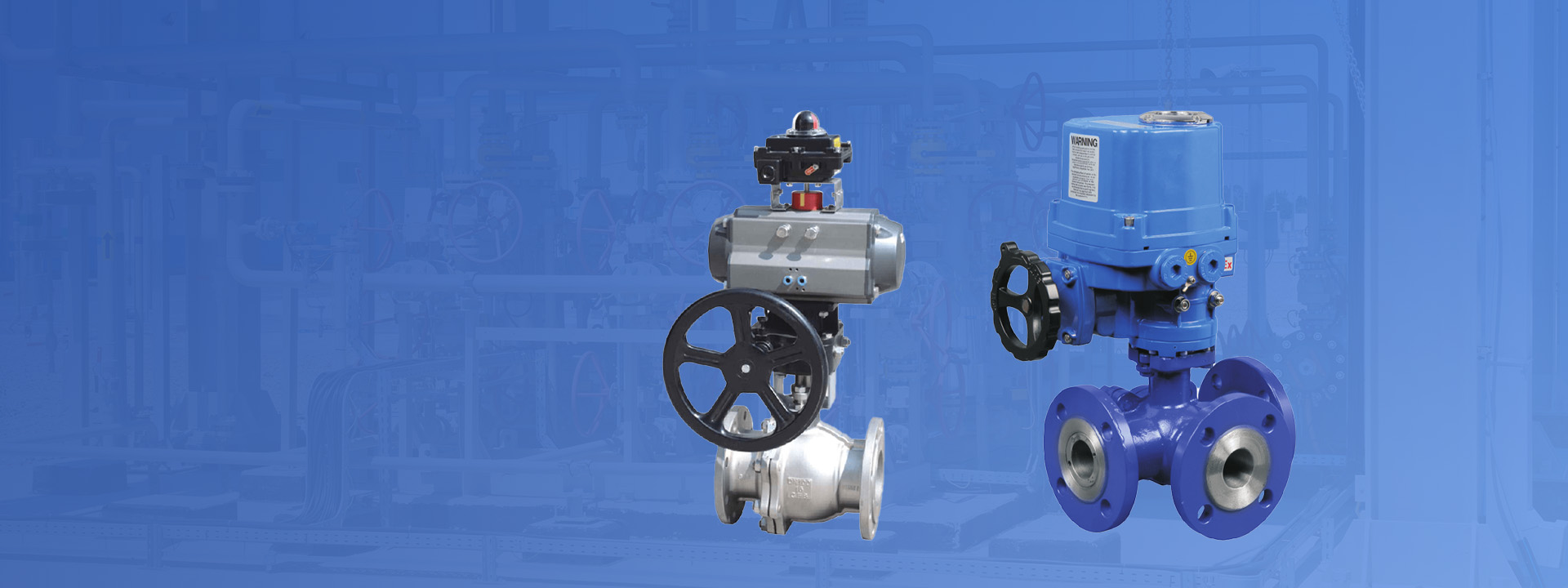

Worm gear hard seal lug butterfly valve

The geometric design of the ASIAV worm gear hard seal lug butterfly valve ensures that the sealing ring is in contact with the valve seat at the moment of final closure, without unnecessary friction and wear; The sealing ring is tightly matched with the valve seat, without the need for constraints when the valve seat is engaged with the sealing ring, ensuring complete sealing performance and low torque; Unique sealing and fire resistance design, providing one-way and two-way sealing options for customers to choose from; The packing adopts unique dust-proof design and low leakage sealing packing active load design; Complex conical sealing ring components can be replaced with wildcard characters.

Gear operated three eccentric lug butterfly valve manufacturer worm gear switch three eccentric lug butterfly valve is mainly metal sealed, which can be sealed by the valve body itself or STL alloy seal, or made into a valve seat with PTFE sealing ring. So our three eccentric lug butterfly valve has good quality and strong applicability.

Gear operated three eccentric lug butterfly valve/stainless steel butterfly valve, API 609, MSS SP-67 temperature and pressure, ASME B16.34 structural length, API 609 end flange, ASME B 16.5 testing standard, API 598 fire protection standard, API-607 American standard hard seat lug butterfly valve design description Sealing structure: soft seal, multi-layer hard seal, elastic hard seal, fireproof soft seal ISO 5211 gasket connection: lug to clamp Operation mode: manual, turbine, electric, pneumatic, hydraulic eccentric structure, centerline structure, single eccentric, double eccentric, triple eccentric structure

Gear operated three eccentric lug butterfly valves are more expensive than gear operated concentric lug butterfly valves. If the temperature and pressure requirements of the medium are not high, concentric butterfly valves can be used instead.

简体中文

简体中文 Japanese

Japanese Korean

Korean Russian

Russian 繁体中文

繁体中文

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们