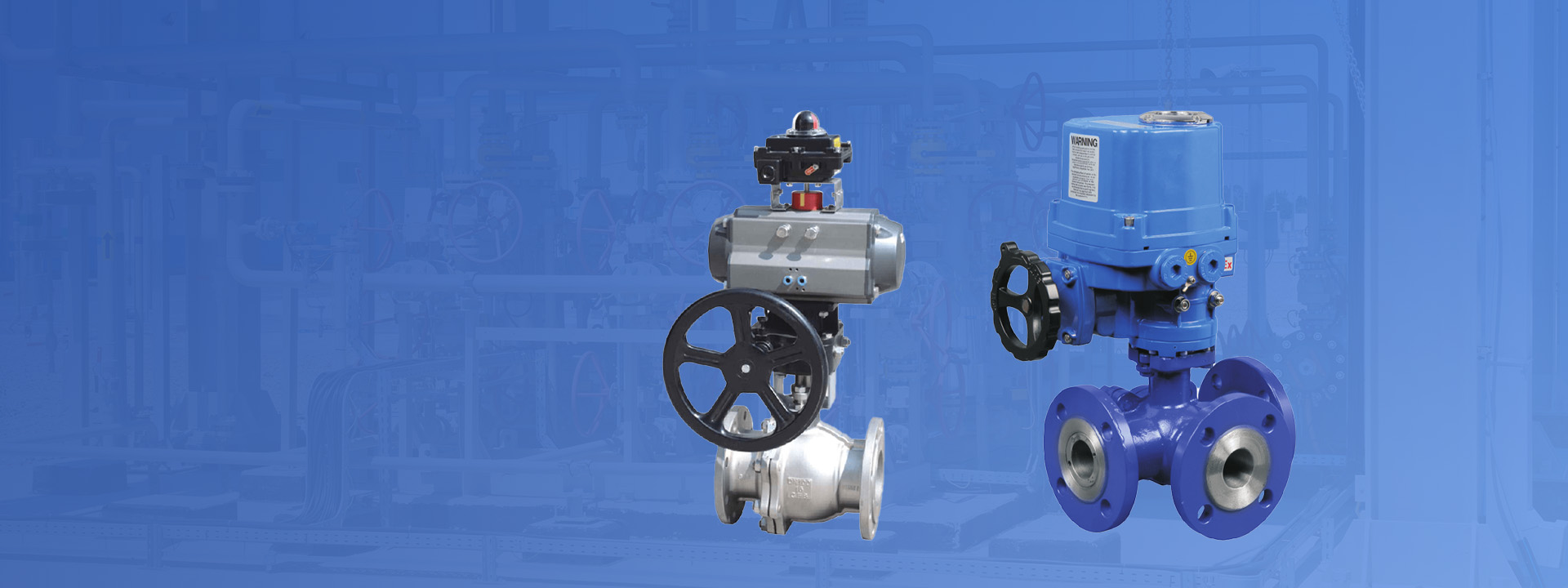

Valve selection

ISO flange connected high vacuum butterfly valve

Vacuum butterfly valve is a commonly used control valve in vacuum systems, characterized by a simple structure and easy operation, suitable for a wide range of vacuum applications. Butterfly valves are disc-shaped valves that can be rotated to achieve fluid flow control and regulation.

Scope of application (Pa) 105~1.310-5 Valve leakage rate (Pa. L/S) ≤ 1.310-6 Medium temperature (℃) -25~80 (NBR) -30~150 (PTFE) Installation position Any flange standard JB919; GB6070

Overview of Vacuum System Vacuum technology is a technology that studies working under conditions where gas pressure is lower than atmospheric pressure. Vacuum systems are widely used in scientific research experiments, semiconductor manufacturing, optical equipment, aerospace, and other industrial fields. In order to achieve control and regulation of fluids in vacuum systems, vacuum butterfly valves have emerged.

Structure and working principle: A vacuum butterfly valve consists of a valve body, valve stem, valve disc, valve seat, and handle. The valve disc is disc-shaped and located inside the valve body, connected to the handle through the valve stem. When the handle rotates, the valve disc also rotates, thereby changing the shape of the fluid channel and achieving the on/off and regulation of the fluid. The butterfly valve has a simple structure, compact size, easy operation, and good sealing performance.

Characteristics and advantages: Vacuum butterfly valves have the following characteristics and advantages:

3.1 Simple Structure: Butterfly valves are composed of fewer components, have a simple structure, and are easy to manufacture and maintain.

3.2 Convenient operation: The butterfly valve adopts a handle rotation operation, which is quick to switch and easy to operate.

3.3 Quick switch: The disc shape of the butterfly valve can achieve quick opening and closing, suitable for scenarios that require frequent switching.

3.4 Smaller volume and weight: Compared to other types of valves, butterfly valves have a smaller volume, lighter weight, and occupy less space, making them suitable for compact vacuum systems.

3.5 Good sealing performance: The tight combination between the butterfly valve disc and valve seat enables the valve to have good sealing performance in the closed state, effectively preventing gas leakage.

Vacuum butterfly valves are widely used in fluid control and regulation in vacuum systems. Common application areas include:

4.1 Vacuum equipment: Used for fluid control of vacuum equipment such as vacuum pumps and vacuum dryers.

4.2 Semiconductor Manufacturing: Used to control the flow of gases and liquids during the semiconductor manufacturing process.

4.3 Laboratory Research: In a research laboratory, the fluid used to control the laboratory vacuum system.

4.4 Industrial Production: Widely used in various industrial production fields, such as chemical, pharmaceutical, food, etc.

When installing and maintaining a vacuum butterfly valve, it is necessary to ensure that the connection port is clean and tightly connected. Before use, the sealing performance and operational flexibility of the valve should be checked. Butterfly valves should be regularly maintained by cleaning the valve body, stem, and disc, and adding lubricants in a timely manner to ensure the normal operation of the valve.

When using a vacuum butterfly valve, the following precautions should be taken:

6.1 Valve pressure range: The appropriate pressure range should be selected according to the actual working conditions to avoid valve damage caused by overpressure.

6.2 Valve Material: Select appropriate valve materials based on the properties of the working medium to ensure the corrosion resistance of the valve.

6.3 Valve operation: Avoid operating the valve with excessive force or too fast to avoid damaging the valve or affecting its sealing performance.

6.4 Maintenance: Regularly maintain the butterfly valve to ensure its normal operation and sealing performance.

Summary: Vacuum butterfly valves are commonly used control valves in vacuum systems, with advantages such as simple structure, easy operation, fast switching, and good sealing performance. It is widely used in fields such as vacuum equipment, semiconductor manufacturing, laboratory research, and industrial production. Before use, attention should be paid to the installation quality and the pressure range of the valve, and regular maintenance should be carried out. By reasonable selection and use, vacuum butterfly valves can achieve stable and reliable control and regulation of fluids in vacuum systems.

简体中文

简体中文 Japanese

Japanese Korean

Korean Russian

Russian 繁体中文

繁体中文

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们