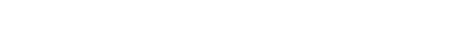

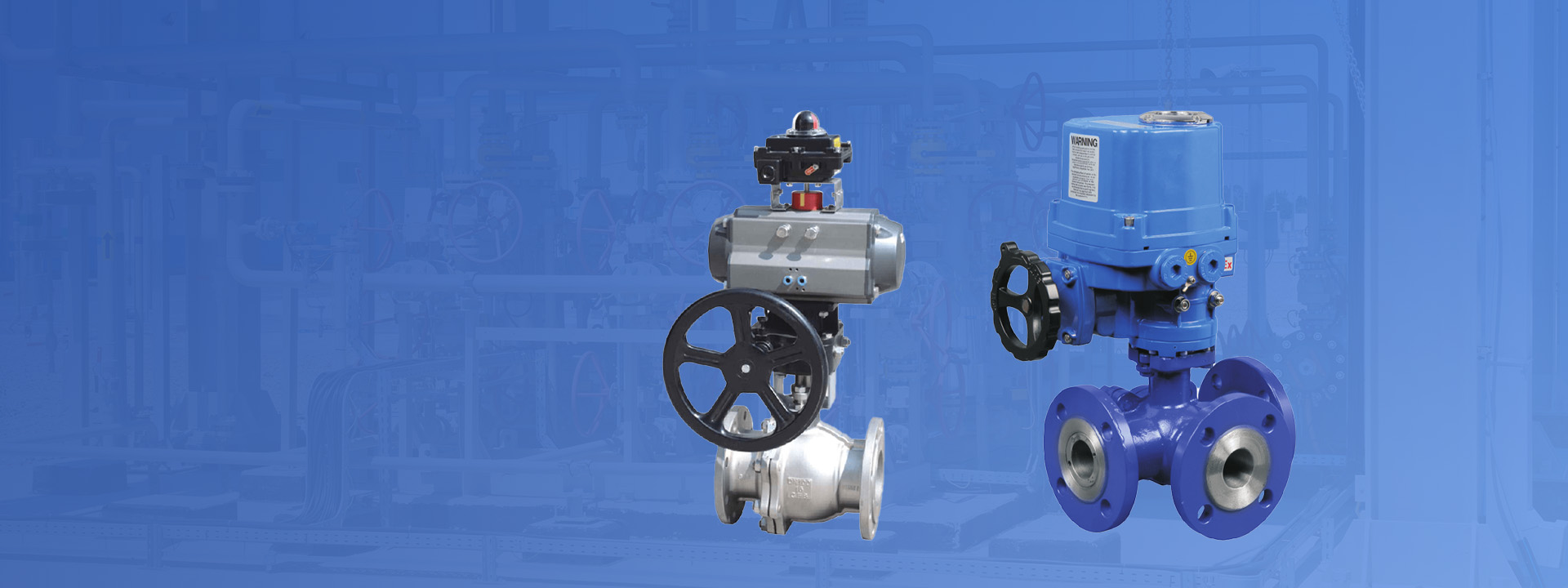

Hand cranked flange American standard ball valve Class600

The valve bracket on the manual flange American standard ball valve Class600 is designed according to ISO 5211, which facilitates the connection of various drivers. Common drive types include manual, electric actuators, pneumatic actuators, and pneumatic/hydraulic actuators. It can be equipped with anti blowing valve stem, position locking with ball valve, and fire and anti-static device.

The leak proof valve stem of a ball valve is fixed with a shoulder at the lower part of the valve stem to prevent the valve stem from flying out and causing abnormal pressure rise inside the valve. In addition, in order to prevent leakage caused by the burning of the valve stem packing in a fire, the thrust bearing is located at the contact position between the valve stem and the lower shoulder of the valve body, forming a sealing seat and playing a sealing role. Prevent leakage and avoid accidents.

The locking device of the ball valve can be used to lock the manual valve when it is fully open or fully closed, preventing the shutdown personnel from operating and causing the valve to move. Locking devices are particularly useful in preventing electric shock caused by valve opening or closing, as well as unpredictable factors that may lead to accidents in flammable and explosive oil, gas, and chemical pipelines or on-site pipelines. When the fire safety structure fixed ball valve is in normal use, it is covered with a valve seat and spherical surface, and the valve seat retainer O-ring and stamped valve body are soft seals with reliable sealing. When the valve seat and O-ring are damaged, the valve seat retainer and valve body will be damaged. Printed with expanded graphite for fire safety purposes.

The anti-static device of a ball valve is designed to prevent static electricity generated by friction between the ball, valve stem, and polytetrafluoroethylene, which can ignite flammable and explosive materials and cause accidents. In this ball valve, a conductive spring is installed between the valve stem and the ball, and between the valve stem and the valve body, So static electricity is the earth, and system safety is guaranteed.

The sealing structure of the leak free valve body and the double cover gasket and O-ring of the valve body and valve cover have a stable switch position. On this basis, external leakage will not be caused by reasons such as fire, high temperature, shock absorption, and uneven opening or closing torque. Double Block Release (DBB)

When the sphere is in the fully open or fully closed position, the emitter material can be released from the center of the cavity to drain and drain the device. In addition, the very central pressure inside the valve chamber can be released to low pressure through its own rescue seat.

Emergency sealing composite injection hole design, the composite injection valve is installed on the valve stem/valve cover and valve body side of the support valve. When the sealing valve stem or valve seat is damaged and leaks, the composite can serve as the second seal for the concealed check valve. The valve installed next to it is used to prevent the compound from flowing out due to the action of the substance, the injection valve on the top of the emitter composite material, and the composite quick connect joint with the injection gun. Reduce the groove of the automatic valve body. When the pressure of the valve body increases abnormally due to unstable factors, the downstream valve seat of the fixed ball valve will be under normal pressure, and the abnormal pressure will be automatically released without damaging the seal of the upstream valve seat.

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们