Stainless steel American standard ANSI Class150 # flange ball valve

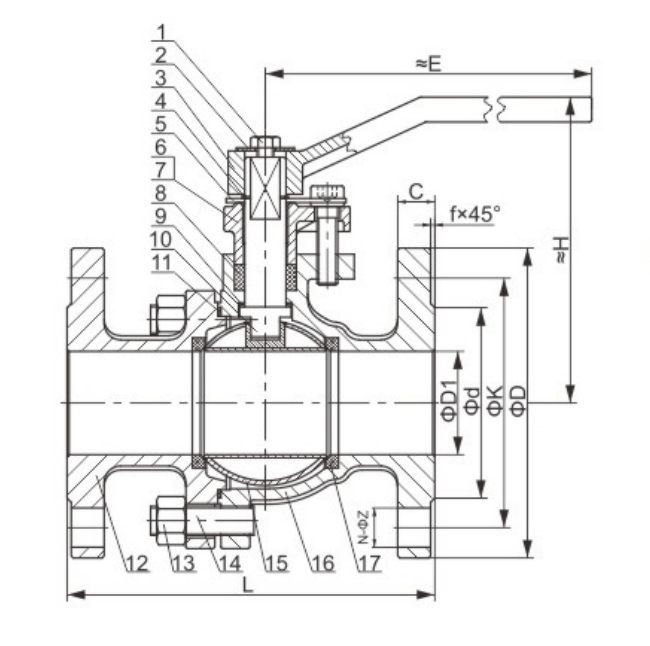

ANSI Class 150 flanged ball valve is a type of switch valve. This valve adopts 150LB American standard and is assembled from stainless steel CF8 and CF8M castings. It is usually a handle switch. Large diameters can be equipped with worm gear transmission devices. The upper flange connection plate complies with ISO 5211 standard and can also be equipped with electric or pneumatic actuators. The ANSI Class 150LB flange ball valve is mainly used to cut off, distribute, and change the flow direction of media in pipelines. Only a 90 degree rotation and a small rotational torque are needed to tightly close it, and the ball valve is suitable for opening and closing.

Nominal pressure or pressure rating: pn1.0-32.0MPa, ANSI rating 150-900, jis10-20k; 2. Nominal diameter or diameter: dn6-900, NPs 1/4-36; 3. Connection methods: flange, butt welding, thread, socket welding, etc; 4. Applicable temperature: -196 ℃~540 ℃; 5. Drive modes: manual, worm gear transmission, pneumatic, electric, hydraulic, pneumatic hydraulic, electro-hydraulic linkage; 6. Valve body materials: WCB, zg1cr18Ni9ti, zg1cr18Ni12mo2Ti, CF8 (304), CF3 (304L), CF8M (316), cf3m (316L), Ti. Different materials can be used for media such as water, steam, oil, nitric acid, acetic acid, oxidizing media, urea, etc.

The fluid resistance is small, and its resistance coefficient is equal to that of a pipe segment of the same length.

Simple structure, small size, and light weight.

It is tightly reliable. Plastic is widely used as a sealing surface material for ball valves, with good sealing performance. It has also been widely used in vacuum systems.

Easy to operate, fast opening and closing, only need to rotate 90 degrees from fully open to fully closed, convenient for remote control.

Easy to maintain, ball valve structure is simple, and the sealing ring is generally movable, making disassembly and replacement relatively convenient.

When the valve is fully open or fully closed, the sealing surfaces of the ball and valve seat are isolated from the medium. When the medium passes through, the sealing surface of the valve will not be corroded.

Widely applicable, with diameters ranging from a few millimeters to a few meters, and suitable for applications ranging from high vacuum to high pressure.

The working principle of American standard flange ball valve is to open or close the valve by rotating the valve core. Ball valve switches are lightweight, small in size, can be made into large diameters, reliable in sealing, simple in structure, easy to maintain, and the sealing surface and spherical surface are often in a closed state, which is not easily corroded by media. They are widely used in various industries. Flange ball valves have their unique advantages, such as frictionless switches, less wear on seals, small opening and closing torque, and the ability to reduce the size of the actuator. Widely used in petrochemical cities with strict water supply and drainage requirements.

NPSD1dKDCfN OZLH EE1/2 "1534.960.3901414-16108791253/4" 2042.969.910016117821251 "2550.879.41101614-1612271021551 1/4" 3263.588.91151824-1614401061551 1/2 "387398.4125124-161651282402" 5092.11120.71501824-191781352402 1/2 "65104.8139.71802024-1919901452803" 7812715242-192031603204 "98157.2190.52302428-192291803205" 123185.7215.92552628-223562525306 "148215.9 241.32802828-223942856308" 198269.9298.53453028-2245738580010 "248323.8362.040534212-25533485 Worm Gear 12" 298381.0431.848536312-25610545 Worm Gear 14348412.8476.353544312-25686635 Worm Gear

首页

首页

Product

Product  News

News  联系我们

联系我们