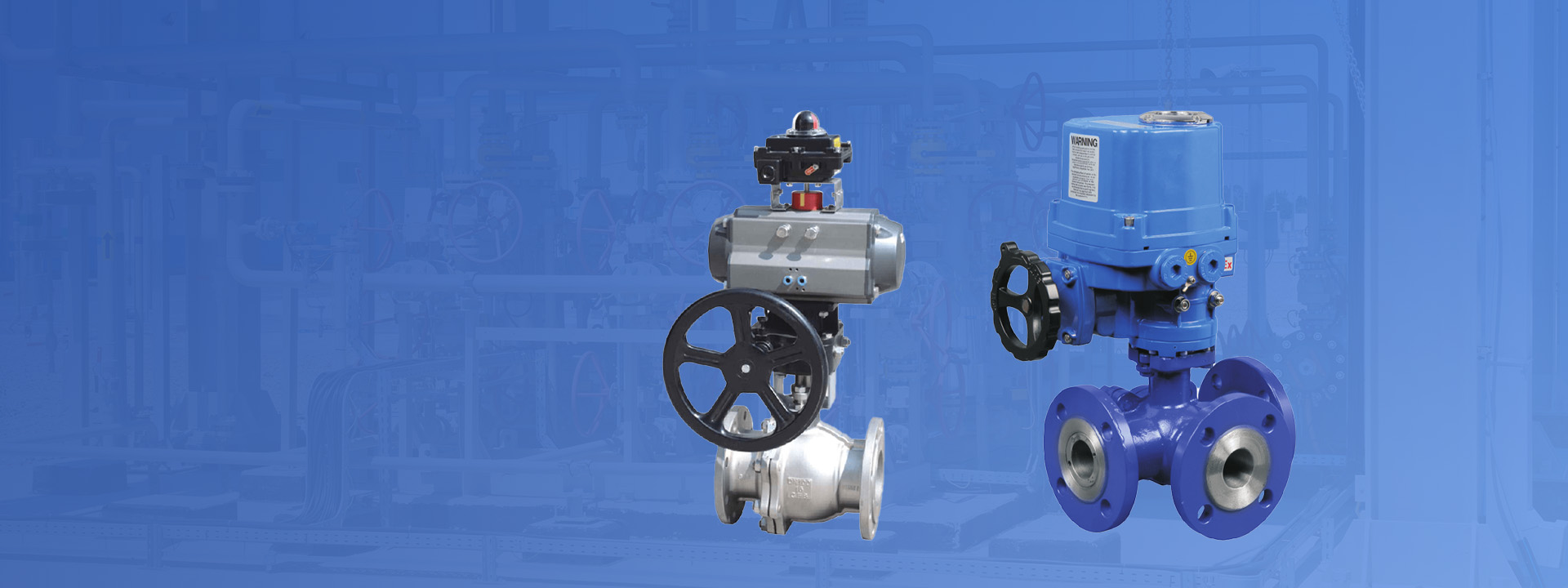

Stainless steel Y-shaped 135 degree three-way ball valve/manual ball plug three-way splitter valve

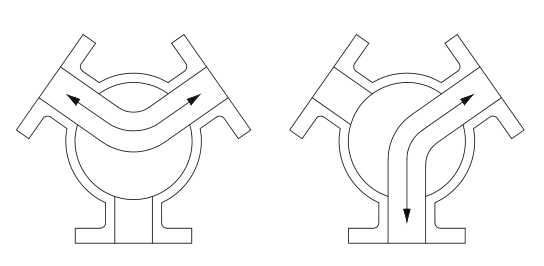

Three way ball valves are used for switching, converting, and dispersing the flow direction of pipeline media. This type of ball valve is widely used in metallurgy, mining, petroleum, chemical industry, power, light industry, transportation industry, and automatic control systems, suitable for converting, mixing, and dispersing media such as liquids, gases, and dust. The Y-shaped 135 angle three-way flange ball valve is a specially designed ball valve used to control the flow of fluid between three directions. Y-shaped design: The name Y-shaped ball valve comes from its internal structural shape, with a Y-shaped flow channel between the ball and the valve body. This design helps reduce the resistance of fluid flowing through the sphere, thereby reducing pressure drop.

1. 135 angle tee: This ball valve has three flange connection ports arranged at a 120 degree angle on a plane. This means that ball valves can control fluid flow from two different directions and guide them to a third direction. Usually, this design is used for applications that require directing fluid from one pipeline to two different pipelines.

2. Flange connection: Y-shaped 135 angle three-way ball valves usually have flange connections, which means they can be connected to the flange connection port of the pipeline system through bolts and nuts. Flange connections are commonly used in high-pressure and high-temperature applications to ensure a stable connection and seal.

3. Purpose: This type of ball valve is widely used in fluid control applications in industrial fields such as chemical, petroleum, natural gas, and power. They can be used to guide fluid from one pipeline to two different pipelines, or to guide fluid from one of the two pipelines to a third pipeline as needed. Please note that the specific specifications and materials of the Y-shaped 135 angle three-way flange ball valve may vary depending on application requirements. Therefore, before selecting and installing, it is important to carefully understand your specific needs and system requirements and choose the appropriate ball valve based on these requirements. The installation and maintenance of ball valves should be carried out according to the manufacturer's guidelines to ensure their normal operation and safety.

首页

首页

Product

Product  News

News  联系我们

联系我们