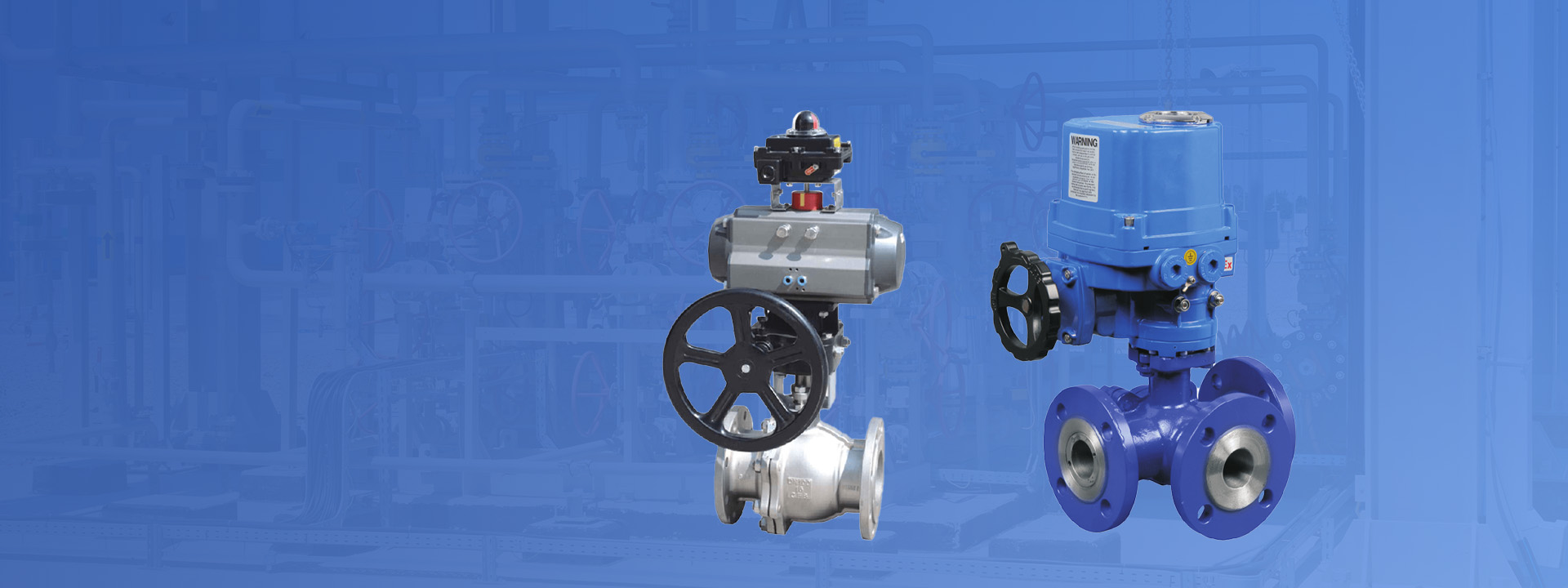

Q347F-16C/P worm gear fixed ball flange ball valve

Worm gear fixed ball flange ball valve is a specially designed ball valve that adopts the structure of worm gear and fixed ball, used to control the flow of fluid. Here are some characteristics and working principles of this ball valve:

Worm gear and fixed ball structure: The key feature of this ball valve is its worm gear and fixed ball structure. Worm gear is a rotating component with gears that controls the position of the ball through manual rotation or electric/pneumatic mechanical devices. A fixed ball is a sphere located within the fluid channel, and its position can be adjusted to open or close the fluid channel by rotating the worm gear.

Fluid control: Worm gear fixed ball flange ball valve is used to control the flow of fluids such as liquids, gases, or steam. By rotating the worm gear, the position of the ball can be changed to open or close the fluid channel, achieving fluid control and regulation.

Flange connection: This type of ball valve usually has a flange connection, allowing the ball valve to be connected to the piping system. Flange connections are typically used in applications that require detachable connections for installation, maintenance, and replacement of ball valves.

Operation method: The worm gear fixed ball flange ball valve can be manually or automatically operated. Manual operation typically involves rotating the worm gear handle to control the opening and closing of valves. Automated operations can use drive devices such as electric worm gears, pneumatic worm gears, or hydraulic worm gears to achieve remote and automated control.

Application areas: This type of ball valve is widely used in industrial fields that require reliable fluid control, including petrochemicals, power, pharmaceuticals, chemical engineering, water treatment, and manufacturing. They are typically used in applications that require high reliability and long lifespan.

In general, the worm gear fixed ball flange ball valve is a fluid control device with reliable control performance, which can work in environments with high pressure, high temperature, and corrosive media. The selection of appropriate ball valve models and specifications should be based on specific application requirements and operating conditions, and follow the manufacturer's product instructions and technical parameters.

首页

首页

Valve selection

Valve selection  news information

news information  联系我们

联系我们